ISO 13609:2021 pdf download – Wood-based panels — Plywood — Blockboards and battenboards.

1 Scope This document establishes requirements for the specifications of blockboards and battenboards for general use, in dry, tropic dry/humid, and high-humid/exterior conditions. It includes requirements of materials, lay-up, physical and mechanical properties, bonding quality, formaldehyde release, conformity verification, and marking. The values listed in this document relate to product properties, but they are not characteristic values to be used in design calculations.

2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 1954, Plywood — Tolerances on dimensions ISO 2074, Plywood — Vocabulary ISO 2426-2:2020, Plywood — Classification by surface appearance — Part 2: Hardwood ISO 2426-3:2000, Plywood — Classification by surface appearance — Part 3: Softwood ISO 2426-4:2018, Plywood — Classification by surface appearance — Part 4: Palm-plywood ISO 9426, Wood-based panels — Determination of dimensions of panels ISO 12460-1, Wood-based panels — Determination of formaldehyde release — Part 1: Formaldehyde emission by the 1-cubic-metre chamber method ISO 12460-3, Wood-based panels — Determination of formaldehyde release — Part 3: Gas analysis method ISO 12460-4, Wood-based panels — Determination of formaldehyde release — Part 4: Desiccator method ISO 12465:2007, Plywood — Specifications ISO 12466-1, Plywood — Bonding quality — Part 1: Test methods ISO 12466-2, Plywood — Bonding quality — Part 2: Requirements ISO 16978, Wood-based panels — Determination of modulus of elasticity in bending and of bending strength ISO 16979, Wood-based panels — Determination of moisture content ISO 16999, Wood-based panels — Sampling and cutting of test pieces ISO 18775, Veneers — Terms and definitions, determination of physical characteristics and tolerances

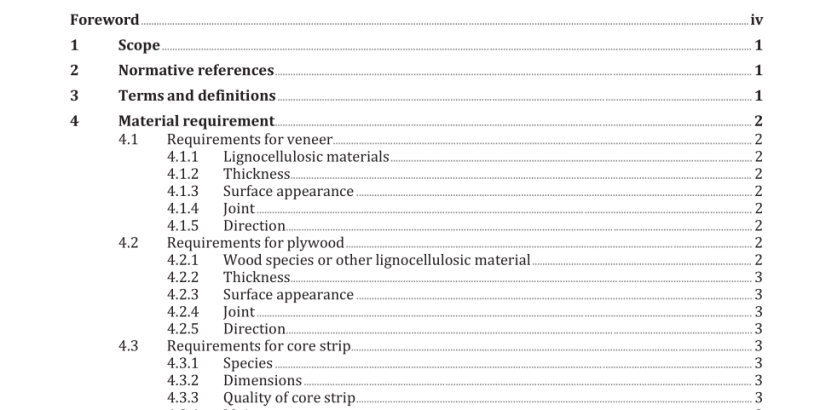

4 Material requirement 4.1 Requirements for veneer The following requirements apply to veneer at the time of pressing. 4.1.1 Lignocellulosic materials Any wood species or other lignocellulosic material is permitted. Veneers shall be identified according to the species, species group, or mechanical properties. When veneers of different species are used to form a layer, these veneers shall be of similar mechanical and physical properties. 4.1.2 Thickness The thickness, t , of veneer shall be 0,55 mm ≤ t ≤ 6,0 mm. When veneers are used to cover a core, the thickness of veneers adjacent to the core shall not be less than 1,5 mm. 4.1.3 Surface appearance The surface appearance of veneer shall be controlled. Surface appearance of the face layer shall satisfy the criteria defined for class II, as given in ISO 2426-2:2020, Table 1 or in ISO 2426-3:2000, Table 1 or in ISO 2426-4:2018, Table 1. Back layer shall not be more than 2 classes inferior to the face layer. If required, veneer classification of other layers shall be carried out in accordance with the limitations defined in ISO 12465:2007, Annex A. 4.1.4 Joint Veneers jointed in width are allowed. If there is a joint in length, it shall be bonded as finger jointing or scarf jointing. End joint is not permitted on face ply.

4.2.2 Thickness The thickness of plywood shall be greater than or equal to 3,0 mm. 4.2.3 Surface appearance The surface appearance of plywood shall be controlled. Surface appearance of the face layer shall satisfy the criteria defined for class II, as given in ISO 2426-2:2020, Table 1 or in ISO 2426-3:2000, Table 1 or in ISO 2426-4:2018, Table 1. 4.2.4 Joint Jointed plywood is not permitted when used for surface layers. 4.2.5 Direction The direction of the grain of the veneer glued to the core shall be determined by considering the veneer lay-up of the plywood. 4.3 Requirements for core strip 4.3.1 Species Within a panel, all strips should be made from the same species. If there are more than one species, similar physical property is required. Otherwise, there shall be an agreement between involved parties. 4.3.2 Dimensions For the blockboard, the width, w, of the strip shall be 7 mm ≤ w ≤ 30 mm. For the battenboard, the width, w, of the strip shall be 30 mm < w ≤ 76 mm. There is no limitation for strip length. The thickness of each strip should not be less than 8,0 mm within a tolerance of ±0,1 mm. Each piece of core strip shall be sized in thickness, individually or after assembly into the core plate. The ratio of width to thickness of each strip should not exceed 3,5.