ISO 10968:2020 pdf download – Earth-moving machinery — Operator’s controls.

1 Scope This document specifies requirements and guidelines for the operator’s controls on earth-moving machinery as defined in ISO 6165, in as far as those controls relate to any direct-control machine. The recommendations given for finger-, hand- and foot-operated controls are not intended to prevent usage of other types of controls, control locations or control movements. This document is not applicable to devices which are not directly related to machine control. NOTE For remote operator control of machines, see ISO 15817. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 3411, Earth-moving machinery — Physical dimensions of operators and minimum operator space envelope ISO 3450, Earth-moving machinery — Wheeled or high-speed rubber-tracked machines — Performance requirements and test procedures for brake systems ISO 5010, Earth-moving machinery — Wheeled machines — Steering requirements ISO 6405-1, Earth-moving machinery — Symbols for operator controls and other displays — Part 1: Common symbols ISO 6405-2, Earth-moving machinery — Symbols for operator controls and other displays — Part 2: Symbols for specific machines, equipment and accessories ISO 10265, Earth-moving machinery — Crawler machines — Performance requirements and test procedures for braking systems ISO 17063, Earth-moving machinery — Braking systems of pedestrian-controlled machines — Performance requirements and test procedures

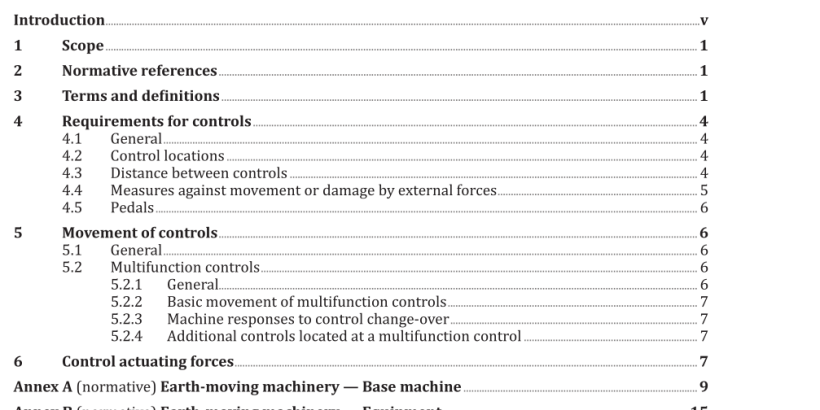

4 Requirements for controls 4.1 General This document recommends that the general requirements and principles of arrangement be followed for other types of controls apart from the one’s listed below, taking into account operator safety and ergonomics. 4.2 Control locations The location of primary controls shall be within the minimum operator space envelope as given in ISO 3411. Primary and secondary controls should also take into account the guidelines given in ISO 6682. 4.3 Distance between controls 4.3.1 The distance between adjacent controls and between controls and other machine parts shall be sufficient to allow operation without unintentional activation of adjacent controls. The overlapping of controls is permissible to provide independent and simultaneous control application.

5 Movement of controls 5.1 General 5.1.1 The type, location and method of operation of typical primary controls shall be according to Annex A for base machine movements, according to Annex B for equipment movements, and according to Annex C for attachment movements. Specific requirements for graders are found in Annex D. Specific requirements for dozers are found in Annex E. Primary controls for equipment not otherwise specified shall follow the same principles as given by Annex B. Primary controls for attachment not otherwise specified shall follow the same principles as given by Annex C. 5.1.2 The movement of the controls in relation to their neutral position shall be in the same general direction as the machine response, unless the combining of controls or customary usage dictates otherwise (e.g. driving control of machines where the operator’s position is located on the part of the machine that can swing, such as the upper structure of an excavator). 5.1.3 If a machine is equipped with an alternative operator’s position with duplicated control arrangements, then both sets of controls shall operate in the same manner. When one set of controls is active, the other set shall be inactive. The active set shall be clearly identified with a visual indicator. An exception would be for mechanically connected dual controls (e.g. duplicate steering wheels, duplicated propulsion controls) where all controls are continuously active. 5.1.4 All controls shall return to their neutral position when the operator releases the control, unless the control has a detent or hold position for continuous activation.

5.1.5 For foot-operated controls where the pedal is operated in two directions (treadle pedal), for example, downward motion of the front of the pedal and downward motion of the rear of the pedal, the pedal shall pivot under the operator’s foot and shall remain at rest in the neutral position.