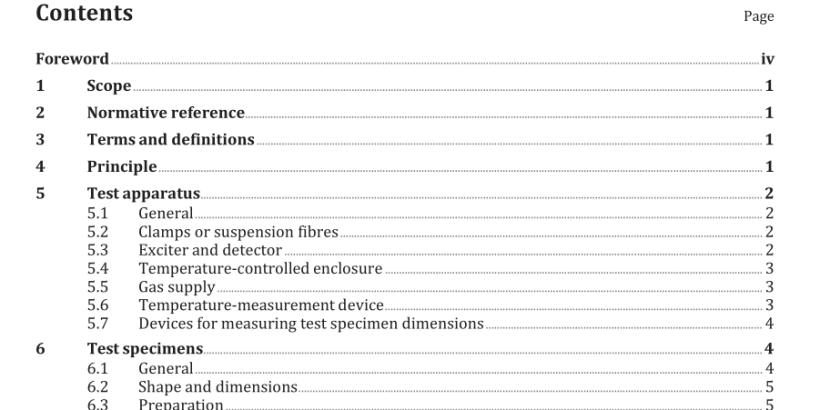

ISO 6721-3:2021 pdf download – Plastics — Determination of dynamic mechanical properties — Part 3: Flexural vibration — Resonance-curve method.

1 Scope This document specifies a bending-vibration method based upon resonance curves for determining the flexural complex modulus E of homogeneous plastics and the damping properties of laminated plastics intended for acoustic insulation, for example systems consisting of a metal sheet coated with a damping plastic layer, or sandwich systems consisting of two sheet-metal layers with an intermediate plastic layer. For many purposes, it is useful to determine these properties as a function of temperature and frequency. 2 Normative reference The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion method, liquid pycnometer method and titration method ISO 1183-2, Plastics — Methods for determining the density of non-cellular plastics — Part 2: Density gradient column method ISO 1183-3, Plastics — Methods for determining the density of non-cellular plastics — Part 3: Gas pyknometer method ISO 6721-1, Plastics — Determination of dynamic mechanical properties — Part 1: General principles

5 Test apparatus 5.1 General The apparatus consists of devices for clamping (method A) or suspending (method B) the specimen, electronic devices (frequency generator and recording device) for exciting the specimen to forced bending vibration, and for measuring the frequency as well as the velocity amplitude of the specimen. For excitation and detection of the vibrations two electromagnetic transducers are situated near the ends of the specimen. The specimen, the clamping or supporting device and the electromagnetic transducers are enclosed in a temperature-controlled chamber (see Figure 1). 5.2 Clamps or suspension fibres If the specimen is clamped at one end, the clamp shall be designed to hold the upper end of the specimen securely and tightly [see Figure 1 a)]. It shall be constructed so that no additional damping of the system occurs. There are two causes of additional damping. — Friction between the test specimen and the clamp: This can be detected by stimulating freely decaying oscillations of the relevant vibrational order. As explained in ISO 6721-1, the type of decay is indicative of different types of deviation from linear viscoelastic behaviour. — Vibration of the clamp: The clamp shall be rigidly mounted on a heavy mass, which acts as a counterweight to the oscillating test specimen. This requires a heavy rigid stand within the temperature-controlled chamber (see Figure 1). If the specimen is tested in the horizontal position, it shall be supported by two fine fibres at vibrational nodes (see 9.4.2). 5.3 Exciter and detector The frequency generator shall be capable of exciting the specimen with the aid of the electromagnetic transducer to oscillations within the frequency range of 10 Hz to 1 000 Hz with a constant force amplitude.

6.2 Shape and dimensions Specimens shall be rectangular bars or strips thick enough to give sufficient bending stiffness, which is critical for the resonance frequency. On the other hand, the thickness shall be sufficiently small when compared to the wavelength of the bending vibration. The specimen thickness shall also be limited to avoid effects due to shear deformation and rotatory inertia if accurate values of E ′ are required. Length-to-thickness ratios of less than 50 shall be avoided if values of E ′ are required to be accurate to within ±5 %, from measurements up to the sixth order of homogeneous, isotropic specimens. The thickness of the layers of a multilayer system will depend on the purpose for which the system was designed. When comparing various systems by the bending-vibration test, the preferred ratio of the mass of the plastic layer to the mass of the basic sheet material is 1:5. The width of the specimens shall be less than one-half of the wavelength used in order to avoid lateral resonance vibrations. A width of 10 mm should be suitable in most cases. The length of the specimens depends on the desired frequency. For specimens clamped at one end, the length shall be sufficiently large to avoid the clamp influencing the vibration significantly. A free length of 180 mm should be used. If the specimen is not clamped, its length shall be 150 mm.