ISO 1628-1:2021 pdf download – Plastics — Determination of the viscosity of polymers in dilute solution using capillary viscometers — Part 1: General principles.

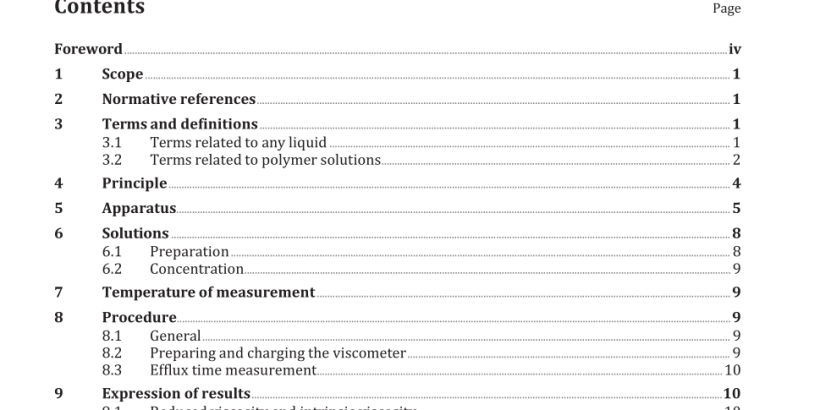

1 Scope This document defines the general conditions for the determination of the reduced viscosity, intrinsic viscosity and K-value of organic polymers in dilute solution. It defines the standard parameters that are applied to viscosity measurement. This document is used to develop standards for measuring the viscosities in solution of individual types of polymer. It is also used to measure and report the viscosities of polymers in solution for which no separate standards exist. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 3105, Glass capillary kinematic viscometers — Specifications and operating instructions ISO 80000-1, Quantities and units — Part 1: General ISO 80000-4, Quantities and units — Part 4: Mechanics 3 Terms and definitions For the purposes of this document, the terms and definitions given in ISO 80000-1, ISO 80000-4 and the following apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https://www.iso .org/obp — IEC Electropedia: available at http://www.electropedia .org/

Note 1 to entry: The dimensions of viscosity are ML T . Note 2 to entry: The units of viscosity are Pa·s. Note 3 to entry: For practical use, the sub-multiple 10 Pa·s is more convenient. Note 4 to entry: Viscosity is usually taken to mean “Newtonian viscosity ”, in which case the ratio of shearing stress to velocity gradient is constant. In non-Newtonian behaviour, which is the usual case with high- polymer solutions, the ratio varies with the shear rate. Such ratios are often called “apparent viscosities ” at the corresponding shear rate.

5 Apparatus 5.1 Capillary viscometer, of the suspended-level Ubbelohde type. The use of a viscometer having the dimensions given in Figure 1 or Figure 2 is strongly recommended. Furthermore, it is strongly recommended that the size of the viscometer be chosen from among those listed in Table 1. The choice is determined by the viscosity/density ratio of the solvent at the temperature of the measurement, as indicated in Table 1. The next-smaller viscometer may also be used. Other types of viscometer listed in ISO 3105 may be used, provided they give results equivalent to those given by the particular size of Ubbelohde viscometer chosen on the basis of the criteria specified in the preceding paragraph. In cases of dispute, an Ubbelohde viscometer shall be used. With automated apparatus, fitted with special timing devices, equivalent results with larger sizes of capillary than those listed for the appropriate solvent viscosity/density ratio in Table 1 can be obtained. 5.2 Viscometer holder, suitable to hold the viscometer firmly in the thermostatic bath (5.3) in the vertical position.

7 Temperature of measurement The temperature shall be chosen with due regard to sufficient solubility and other technical requirements, but kept constant for any particular polymer/solvent system. The temperature tolerance shall be specified. A temperature of 25 °C ± 0,05 °C shall be chosen whenever possible. If another temperature is used, use the temperature that was agreed between the parties concerned and stated in the test report. 8 Procedure 8.1 General Measure the efflux times for the solution and the solvent successively in the same viscometer, using the procedure described in 8.2 and 8.3. 8.2 Preparing and charging the viscometer 8.2.1 Maintain the bath at the specified test temperature. 8.2.2 Charge the dry, clean viscometer (the cleaning procedure is specified in Annex A ) by tilting it about 30° from the vertical and pouring sufficient liquid through tube L (see Figure 1 or Figure 2) so that, when the viscometer is returned to the vertical, the meniscus is between the filling marks G and H. Avoid trapping air bubbles in the viscometer. The initial filling may be carried out away from the bath. 8.2.3 Mount the viscometer in a holder in the bath, ensuring that tube N is vertical. Allow time for the charged viscometer to reach the temperature of the bath. Usually, 15 min will suffice if the measurement is to be made at 25 °C. At higher temperatures, longer times is necessary. Unnecessary delays should be avoided as it is found that the most consistent results are obtained shortly after temperature equilibrium is attained with a freshly charged viscometer.