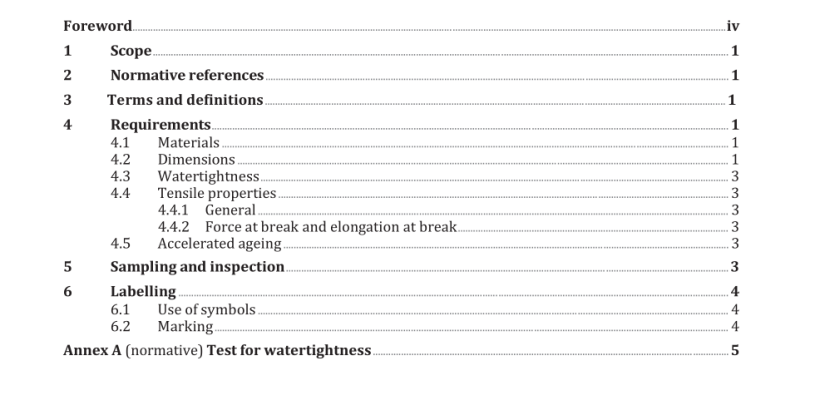

ISO 25518:2021 pdf download – Single-use rubber gloves for general applications — Specification.

1 Scope This document specifies the physical requirements and sampling and testing methods for single-use rubber gloves, made from natural rubber latex, synthetic rubber latex or rubber solution, intended for general applications, but not gloves intended for medical purposes. It does not cover the safe and proper usage of the gloves.

2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminology databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https://www.iso .org/obp — IEC Electropedia: available at https://www.electropedia .org/

4 Requirements 4.1 Materials Gloves shall be manufactured from suitable materials. Any pigment, surface treatment, lubricant or powder used shall be non-toxic and shall be disclosed on request. Substances used for the treatment that could be transferred to the skin during use shall not cause any harm. 4.2 Dimensions When measured at the points shown in Figure 1 , gloves shall comply with the dimensions for length (L) and palm width (W ) given in Table 1, using the inspection level and acceptance quality limits (AQL) given in Table 3.

4.5 Accelerated ageing Accelerated ageing shall be conducted in accordance with the method specified in ISO 188. Test pieces can be prepared either by ageing the gloves at 70 °C ± 2 °C for 168 h ± 2 h or at 100 °C ± 2 °C for 22 h and cutting the test pieces from the aged gloves or by cutting the test pieces from unaged gloves and ageing the test pieces at 70 °C ± 2 °C for 168 h ± 2 h or at 100 °C ± 2 °C for 22 h. Tensile testing is then conducted as described in 4.4. The results shall comply with the requirements given in Table 2, using the inspection level and AQL as in Table 3 . For gloves that are older than 6 months from the date of manufacture or for which the date of manufacture is unknown, no accelerated aging shall be conducted and the tensile properties need only conform to the “after accelerated aging ” values in Table 3 . The 6-month period should begin with the first day of the month immediately after the one in which the gloves were manufactured. 5 Sampling and inspection For referee purposes, gloves shall be sampled and inspected in accordance with ISO 2859-1. The inspection levels and acceptance quality limits (AQLs) shall conform to those specified in Table 3 for the characteristics listed.

6 Labelling 6.1 Use of symbols Appropriate international symbols may be used for marking purposes in addition to the wording given. The language used for marking shall be as agreed upon between the interested parties. 6.2 Marking Packages intended to facilitate safe transport and storage of the gloves shall be clearly marked with the following: a) the name or trademark of the manufacturer or supplier; b) the material used; c) the words “TEXTURED ” or “SMOOTH”, “POWDERED ” or “POWDER-FREE ”, or words to that effect for the appropriate glove finish; — Powdered surface. NOTE 1 Powdered gloves are gloves which a powder has been applied on as part of the manufacturing process, generally to facilitate donning. Powdered gloves have a maximum powder limit of 15 mg/dm . — Powder free surface. NOTE 2 Powder-free gloves are gloves which have been manufactured without the deliberate application of powdered materials. Powder-free gloves have a maximum of 2,0 mg powder residue limit per glove. d) the size, as specified in Table 1; e) f) the manufacturer’s identifying lot number; the words “DATE OF MANUFACTURE ”, or words to that effect, and the year (in four digits) and month of manufacture; g) the approximate number of gloves; h) instructions for storage; i) the words “NOT FOR MEDICAL OR INDUSTRIAL USE ”, or words to that effect.