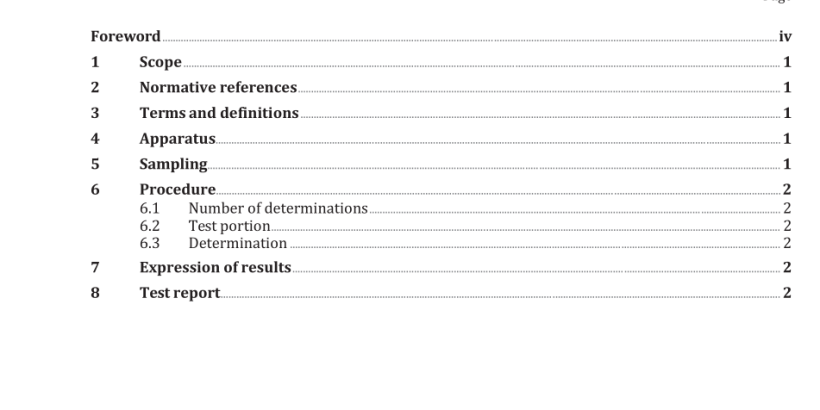

ISO 787-2:2021 pdf download – General methods of test for pigments and extenders — Part 2: Determination of matter volatile at 105 °C.

1 Scope This document specifies a general method of test for determining the mass fraction in percent of matter volatile at a temperature of 105 °C in a sample of pigment or extender. This method is applicable to pigments and extenders that are stable at 105 °C.

2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 15528, Paints, varnishes and raw materials for paints and varnishes — Sampling ISO 18451-1, Pigments, dyestuffs and extenders — Terminology — Part 1: General terms

3 Terms and definitions For the purposes of this document, the terms and definitions given in ISO 18451-1 apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https://www.iso .org/obp — IEC Electropedia: available at https://www.electropedia .org/

4 Apparatus 4.1 Weighing bottle, squat form, wide-mouthed, with ground glass stopper. 4.2 Oven, capable of maintaining the temperature at (105 ± 2) °C. 4.3 Balance, accurate to 0,1 mg. 4.4 Desiccator, containing an efficient desiccant. 5 Sampling Take a representative sample of the product under test, in accordance with ISO 15528.

6 Procedure 6.1 Number of determinations Carry out the determination in duplicate. 6.2 Test portion Heat the weighing bottle (4.1), with the stopper removed, in the oven (4.2) at (105 ± 2) °C for 2 h. Allow to cool in the desiccator (4.4), insert the stopper and weigh to the nearest 1 mg. Spread (10 ± 1) g of the sample in a uniform layer on the bottom of the weighing bottle, insert the stopper and weigh to the nearest 1 mg. It can be necessary to reduce the mass of the test portion for pigments and extenders with a high bulk volume. The use of a test portion smaller than that specified shall be stated in the test report. 6.3 Determination Heat the weighing bottle and contents, with the stopper removed, in the oven (4.2) at (105 ± 2) °C for a minimum of 1 h. Allow to cool in the desiccator (4.4), insert the stopper and weigh to the nearest 1 mg. Repeat the heating for at least 30 min, allow to cool in the desiccator (4.4), insert the stopper and again weigh to the nearest 1 mg. Repeat the procedure until two successive results differ by no more than 5 mg. Record the lower mass. If the results of the two determinations differ by more than 10 % of the higher value, repeat the whole procedure in this clause.

7 Expression of results The matter volatile at 105 °C is calculated as the mass fraction ω in percent by Formula (1): ω = m 1 − m 2 m 1 − m 0 × 100 (1) Where, ω m 1 is the matter volatile at 105 °C of the test portion, as mass fraction in percent; is the mass, in grams, of the weighing bottle and the test portion; m 2 is the mass, in grams, of the weighing bottle and the residue; m 0 is the mass, in grams, of the weighing bottle. Calculate the mean of the two determinations, if they do not differ by more than 10 % of the higher value and report the result to the nearest 0,1 %. Report results between 0 % and 0,1 % as “less than 0,1 %”.

8 Test report The test report shall contain at least the following information: a) all details necessary to identify the product tested; b) a reference to this document, i.e. ISO 787-2:2021; c) the result of the test as indicated in Clause 7;

d) any deviation, by agreement or otherwise, from the procedure specified, particularly another test temperature; e) f) any unusual features (anomalies) observed during the test; the date of the test.